Follow our Photo Tour of the Path to Commission for SSBN-826

%20(1).png)

June 2024

USS District of Columbia's Section 6-7, which are the Mid- to Forward-Engine Room, are being turned from vertical to ship’s positions.

January 2024

Newport News Shipbuilding (NNS) delivered the stern for first-in-class submarine District of Columbia (SSBN-826) to General Dynamics Electric Boat. This marks a major milestone for the U.S. Navy’s Columbia Class submarine program.

February 2023

HII’s Newport News Shipbuilding (NNS) broke ground on the Multi-Class Submarine Production Facility, which will be one of three new facilities enabling the construction and delivery of the Columbia and Virginia Class submarines.

August 2022

Leonardo DRS, Inc. successfully completed factory acceptance testing and shipment of the first production unit of the main propulsion motor for the Columbia Class SSBN. The motor was then shipped to General Dynamics Electric Boat for integration into the USS District of Columbia, the lead ship of the Class.

June 2022

General Dynamics Electric Boat welder Maria Betance-Pizzaro welds the initials of Congresswoman Eleanor Holmes Norton, USS District of Columbia's (SSBN-826) Sponsor, onto a plate during the Keel Laying ceremony.

May 2022

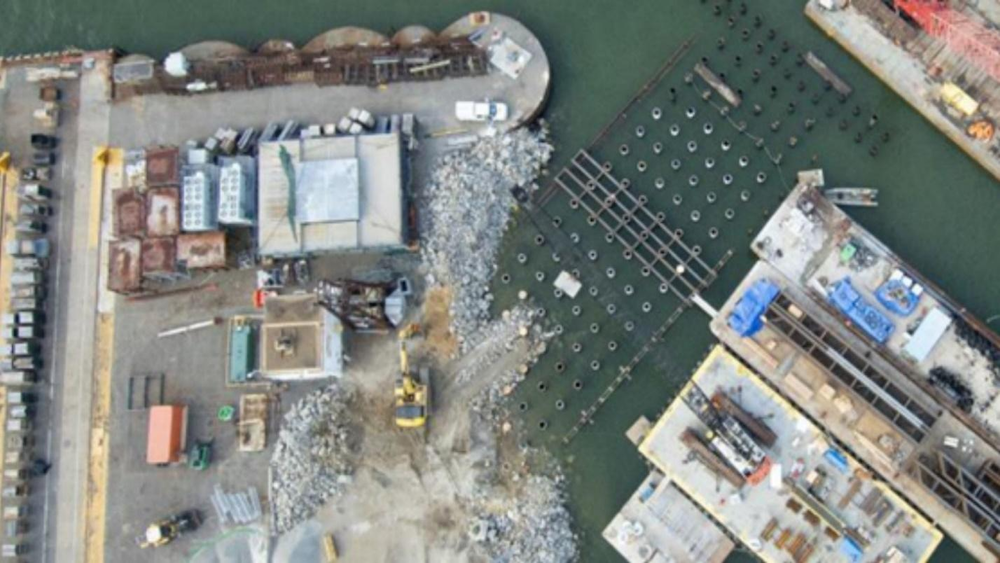

At HII’s Newport News Shipbuilding (NNS) division, a new pier now under construction in the North Yard will be a crucial piece in the Columbia-Class Submarine Program, where NNS plays a major supporting role.

November 2021

OTB Holland arriving at General Dynamics Electric Boat’s (GDEB) Groton Shipyard. Designed by Bristol Harbor Group, Inc. (BHGI) in R.I. and constructed by Bollinger Shipyards, LLC, of Lockport, LA, OTB Holland was purpose-built to support the delivery of Columbia Class SSBNs.

October 2020

The Official Start of Construction is the first day of the Fiscal Year for which a submarine is appropriated. For the District of Columbia (SSBN-826) construction officially started 1 October 2020. At official start, the District of Columbia was ~10% complete as advanced construction on critical long lead items began several years earlier.

August 2020

The Naval Foundry and Propeller Center (NPPC) in Philadelphia, made the first casting for the Columbia-Class submarine. The Honorable James F. Guerts, Assistant Secretary of the Navy for Research, Development and Acquisition, along with senior Navy leaders and congressional members, visited NPPC to see the historic event which represented one of the largest in American history weighing over 200,000 lbs. Guerts noted it was an “Awesome sight to see.”

May 2019

With the press of a button, a plasma-burning machine cut the first steel plate that will be used to build USS District of Columbia (SSBN-826) during a ceremonial first-cut-of-steel event at Huntington Ingalls Industries (HII) Newport News Shipbuilding (NNS) facility.

May 2019

Captain Jon Rucker, then Columbia SSBN Program Manager, highlighted Columbia’s “first pour,” stating “the first component of the lead ship Columbia was poured on May 1. So 175,000 pounds – I won’t tell you what it is, I’m not allowed to – 175,000 pounds, first component for Columbia, on schedule.”